If you have any questions, or would like to make a purchase, please call Small Tools Inc. at (216) 732-5980 or send an email to Small Tools Inc. on our contact

page using the form provided.

Automatic Parts

Rapid traverse brakes, yoke assemblies, glands, adjusting screws, switch operating pins, speed and feed dogs, cam roll sub assemblies…

SC & CNC Parts

Parts for Warner & Swasey SC10, SC15, SC20, SC24, SC25, SC28, SC32, SC36, SC45, WSC-8, WSC-12, WSC-15, WSC-24, QCM-6, TITAN, etc.

Turret Lathe Parts

Shafts, gaskets, indicators, clutch assemblies, gauges, pumps, sprockets, yokes, splines, worm shafts, rapid keys, cross feed clutches…

Machine Manuals

Repair and maintenance manuals for turret lathes, single spindle chuckers, single spindle bar machines, multi spindle automatics, CNC, etc.

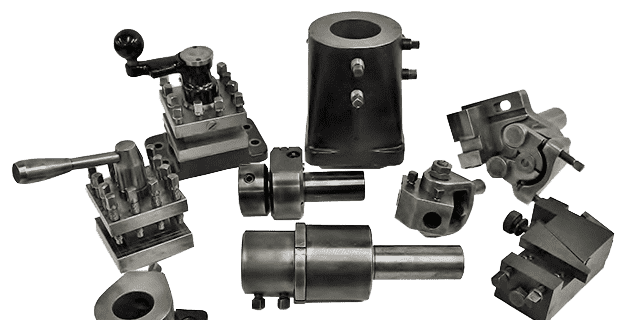

Machine Tools

Flange tool holders, square turrets, floating reamer holders, front and rear cutter blocks, end facers, turning heads, platen slides…

GAHR MACHINE COMPANY

© 2023

ABOUT US

Founded in Cleveland, Ohio in 1947, the Gahr Machine Company is a supplier of Warner & Swasey parts, tools, manuals, and accessories for all types of industrial manufacturing machinery.

GET IN TOUCH

(216) 732-5980

Mon-Fri, 8:00am - 4:30pm

We reply within 24 hours